INTRODUCTION

The term Lean manufacturing refers to the application of Lean practices, principles, and tools to the development and manufacture of physical products. Many manufacturers are using Lean manufacturing principles to eliminate waste, optimize processes, cut costs, boost innovation, and reduce time to market in a fast-paced, volatile, ever-changing global marketplace.

The History

The method, also known as lean production or just-in-time production (JIT), dates back to the late 1940s when Toyota developed its operating model called Toyota Production System (TPS). Later on, in 1988, John Krafcik established the term “lean”. The emergence of the lean manufacturing principles is attributed to James Womack and Daniel Jones who defined the method’s 5 principles in 1996: value specification; mapping the value stream; creating value flow; establishing pull system; pursuing perfection. The principles forming a production cycle are the heart of Lean philosophy and Lean thinking. Originating in the manufacturing world, today the method is successfully applied as a management method across industries and domains.

TOYOTA PRODUCTION SYSTEM (TPS)

The Toyota Production System (TPS) or “The Toyota Way” is an operational model which emerged in the early 20th century in Japan as a management system for organizing manufacturing and logistics processes. The backbone of TPS is the just-in-time production (JIT) system, created by Mr. Taiichi Ohno (a Japanese industrial engineer and businessman).

The two pillars of the Toyota Way are continuous improvement and respect for people. They are foundational to the understanding of what lean manufacturing is all about and where its principles are derived from.

The core purpose of just-in-time production as a part of TPS is to remove all wasteful activities from the processes. By reducing and eliminating non-value-adding activities (wastes) from production, the method aims to achieve continuous improvement. For instance, if you work in an environment where changeover times are significant and there are multiple job classifications, applying the JIT system would mean looking for ways to reduce changeover times and eliminating job classifications. By doing so, you not only provide greater flexibility to the people, you are empowering their ability to use their full potential instead of doing the same thing over and over.

Key Principles and Concepts of Lean Manufacturing

Lean Manufacturing relies on five key principles. Identify value. Map the value stream. Create flow. Establish a pull system. Pursue perfection. At its core, Lean manufacturing is defined as the production strategy to reduce times for delivery and response to customers’ inquiries. It does that by eliminating all processes which don’t bring value.

Practicing Lean Manufacturing

A prerequisite to successfully practicing the Lean manufacturing strategy is understanding its core principles. To practice Lean Manufacturing, you can follow the steps below. Identify value: Specify what is the specific value that the customer desires. Map the value stream: Identify the value stream cycle for each product or service providing value to your customers and remove the ones that don’t add value. Create flow: Once the value-adding steps are identified, aim to create a continuous flow of value in your process. Establish a pull system: Allow people to pull work instead of pushing work on them. Pursue perfection: Continuously improve to reduce the time and steps required to deliver value to your customers. Continuous improvement is a foundational part of the Lean culture. The commitment to always be on the lookout for better ways to do work is an essential part of what Lean production teaches. Through the use of techniques such as mapping the value stream and establishing a pull-based production system, you are ready to start practicing Lean.

1. Value stream mapping

The value stream mapping is the Lean practice of visualizing all necessary steps in a work process for delivering value to the customer. The technique allows you to represent visually every stage and work item in your process. By doing so, through value stream mapping you can easily identify and eliminate wasteful steps and activities and redesign your process to achieve a healthy flow of work.

2. Demand-based flow (pull) manufacturing

Establishing a pull system is one of the Lean manufacturing principles designed to help reduce waste from the production processes. The term refers to committing to work only when there is an actual demand for it. The practice of pull allows you to optimize your resources, reduce overstocking and deliver faster.

3. Continuous improvement

Continuous improvement is the backbone of Lean philosophy. All organizational efforts are focused to increase customer satisfaction, eliminate waste, and optimize work processes through constant examination of how to process work. Continuous improvement allows you to improve the quality and flow of work, simplifying work processes, reducing waste such as defects, among other benefits.

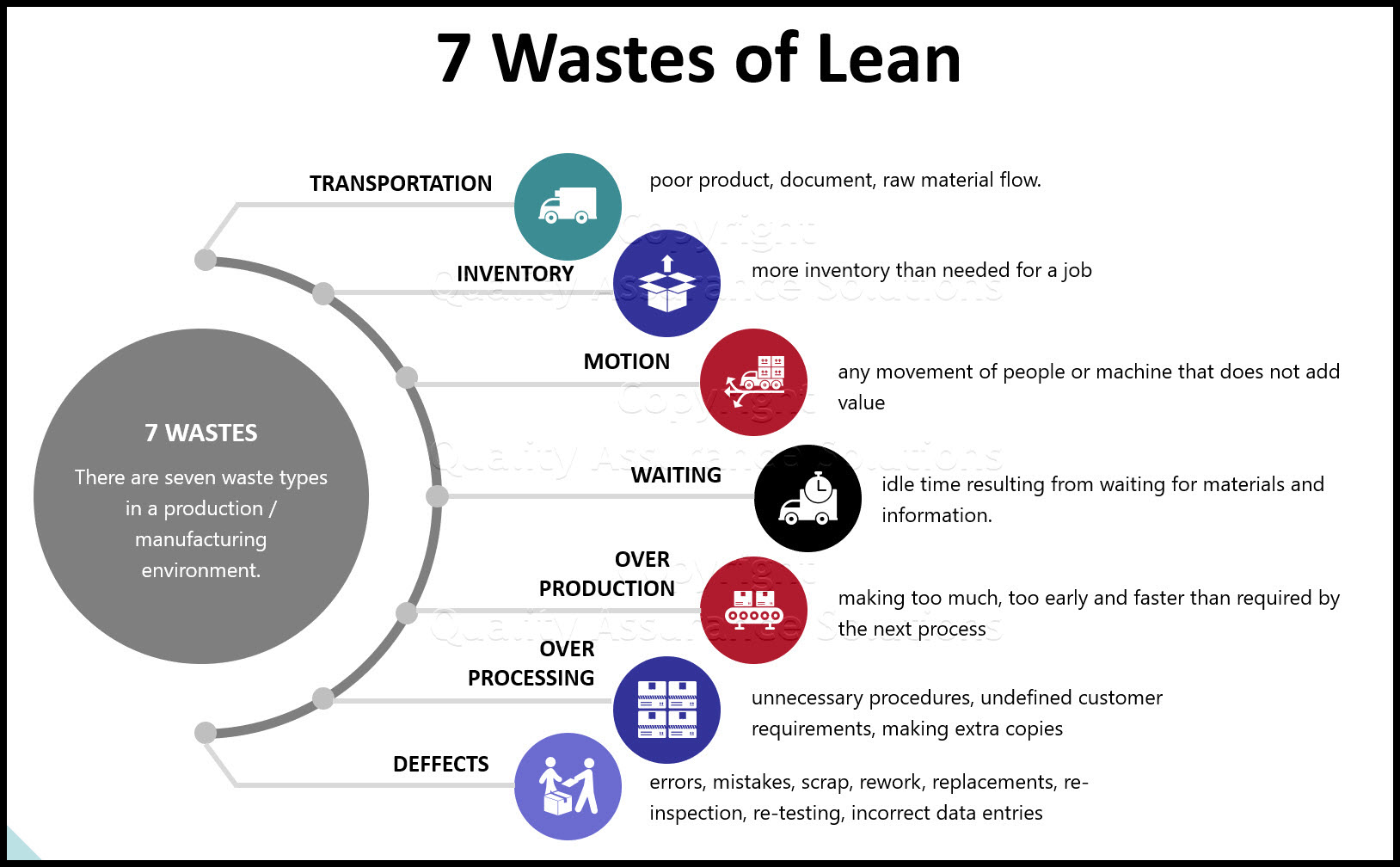

Types of Waste in Lean Manufacturing

Eliminating waste is an integral part of what Lean manufacturing actually is. Following the Lean guidelines means eliminating, reducing, and simplifying work processes. In Lean, there are seven types of waste that should be eliminated from the workflow through continuous improvement.

1. Overproduction

Overproduction is a type of waste in Lean manufacturing that refers to producing or generating work in excess of what is in demand which leads to additional costs for transportation, resources, waiting time, rework, etc.2. Inventory

The inventory type of waste is related to an excessive overstocking of materials or resources to meet unexpected customer demands. However, in most cases, the end result of this inventory is increased storage costs and no added value for customers.3. Motion

The motion waste type refers to any unnecessary movement of people or equipment which affects production time, the safety of the working environment, and workplace organization. This can include moving, lifting, reaching, etc.4. Defects

Defects are a type of Lean manufacturing waste that refer to any product or service which is not fit for use and requires rework or scrapping altogether. All defects lead inevitably to additional costs and do not add value to the customers.5. Over-processing

The waste refers to all excess work that is not required by the customer and leads to additional costs and spending of resources. The result is an increased end price a customer may not be willing to pay for. This can be an additional product functionality or adding more steps in a workflow process.6. Waiting

Waiting is a type of waste in Lean manufacturing that refers to any type of service which is not in motion: waiting on materials or suppliers, equipment waiting to be fixed, people waiting on approval, etc.7. Transport

The transport waste in Lean manufacturing refers to any excessive movement of materials or resources which turns out costly, can negatively affect the quality, and does not add value to the end product.The Goals

Among the most prominent objectives of the Lean manufacturing method is creating efficiency through continuously examining the current processes and improving. To achieve this, Lean has 4 different goals. To improve the quality of delivered value (products or services). To reduce delivery times and times to respond to customer requests. To optimize work processes by eliminating waste (non-value-adding steps). To reduce costs by meeting customer demands with as little resources as needed.

The Advantages

Before jumping to implement Lean manufacturing in your business, analyzing the advantages of the production methodology is crucial to align your expectations with reality. Along its evolution path, the method has proven its potential to bring:

- Improved quality performance

- Streamlined processes

- Increased productivity

- Increased employee satisfaction and morale

- Increased profits

5S

The Lean philosophy proposes a variety of techniques to facilitate the successful implementation of production methods such as Lean manufacturing. 5S is one of the most important and widely applied Lean tools to achieve continuous improvement (kaizen). The method represents a sequence of 5 consecutive steps to workplace optimization. The goal of the 5S method is to maximize the efficiency of the workplace and by that to boost productivity. The 5S stands for:

- Sort: Refers to actual sorting of necessary from unnecessary tools and equipment.

- Set in order: Refers to organizing the work environment to minimize process waste.

- Shine: Refers to keeping the equipment in a perfect state and utilizing it to its full potential.

- Standardize: Refers to work process standardization.

- Sustain: Refers to the ability to sustain all improvements and set a trend of continuous improvement.

Best Lean Manufacturing Tools

Lean manufacturing offers the use of multiple tools and techniques to achieve the goals you set out to achieve. Depending on your business environment, the most suitable Lean manufacturing tools may differ. Here’s a handful of the most popular, useful, and widely applied tools:

- Kanban

- Kaizen

- Value Stream Mapping

- 5S

- Plan-Do-Check-Act (PDCA)

Examples of Lean Manufacturing

The universality of the Lean production principles is what allows its expansion outside the manufacturing realm. Examples of Lean Manufacturing practices can be found below.

- Truck Manufacturing: Improving production levels and efficiency.

- Customer Service: Streamlining the work process by mapping the value stream.

- Process Automation: Improving transparency and flow tracking.

- Innovation culture: Improving learning and knowledge sharing.

Best Books For Lean Manufacturing

The evolutionary nature of Lean manufacturing offers extensive literature both theoretical and practical. Some of the best books for lean manufacturing are listed below:

- Toyota Production System, Beyond Large Scale Production”, Taiichi Ohno, 1978

- A revolution in manufacturing”, Shigeo Shingo, 1985

- Just-In-Time for Today and Tomorrow”, Setsuo Mito, Taiichi Ohno, 1988

- The Machine That Changed the World”, Daniel Roos, Daniel Jones, James Womack, 1990

- Lean Thinking: Banish Waste and Create Wealth in Your Corporation”, James Womack, Daniel Jones, 1996

In Summary

The Lean manufacturing production method is designed to help reduce both the time for production and response times to customers and from suppliers. The method relies on five key principles.

- Identify value.

- Map the value stream.

- Create flow.

- Establish a pull system.

- Pursue perfection.